Post No. 7,

We need to start growing Bamboo, all we can as fast as we can.

It breaks my heart to see people who lost their homes in the recent Western wildfires rebuilding the same kinds of combustible houses in the same already-growing-back forests, setting themselves up to lose everything yet again, when their new homes could be so fireproof as to serve as a refuge, shelter, from wildfire.

In Post No. 2, Portland Cement is Poison, I said that I see a way to cut the cost of construction using geopolymer cements, preferably Blue World Crete, and bamboo. Bamboo is an amazing resource: some timber bamboos grow as tall as 75 feet in one year. They may take 3 to 7 years to “harden off” and be ready to harvest—one year for pulp—but even pine trees grown for pulp take 40 years to mature. Bamboos can have tensile strengths as high as 45,000 psi, equal to mild steel. Geopolymer cements will soak into and “mineralize” bamboo and other woody aggregate and reinforcing, protecting them from fire and rot, possibly for thousands of years. I don’t see us reinforcing concrete bridges or high-rises with bamboo, though the right architect might surprise me. But for homes and commercial buildings a few stories high, steel reinforcing is overkill, and bamboo will do nicely.

I also wrote about clean steel in Post No. 4. Carbon neutral steel will help hugely to decarbonize construction. But like all woody biomass, bamboo is about half carbon, and encasing it in concrete sequesters that carbon, probably far longer than the life of the building. That’s not carbon neutral, it’s carbon negative. Use carbon-sequestering cements, and your new home could take a nice little bite out of climate change.

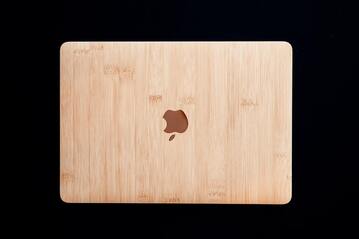

The problem is, we don’t grow bamboo commercially anywhere on this continent, that I can find. We will need megatons of the stuff, and burning bunker oil to import it from Asia would negate its value as a low-carbon product. Bamboo can be made into strong, beautiful plywood and laminated lumber, flooring and furniture, kitchen utensils, high-quality paper, natural fiber or rayon for clothing, surfboards, skateboards, bicycle frames, and musical instruments; anything you can make out of wood, and some things usually made of steel or aluminum.

Natural mechanically-processed bamboo fiber is soft, antifungal and antimicrobial, absorbent yet fast drying, anti-static, warm in cool weather and cool in warm. The process for making rayon--artificial cotton--from bamboo or any other cellulose uses some nasty chemicals. Its developers claim that a new processes called Lyocell is much cleaner, and bamboo rayon cloth is supposed to be nicer on the skin than cotton, great for towels, underwear, and bedsheets.

You don’t have to replant bamboo: the root mass sends up so many new shoots each spring that you can harvest some for food without reducing your timber crop. It yields 50 times as much fiber per acre as cotton, while its fallen leaves build a nice layer of humus to enrich the soil. Unlike chemical and water-thirsty cotton, bamboo needs no fertilizers, herbicides or pesticides. It is even easier to grow than hemp, and approximately as useful. And we need plantations of it all across the country, or I can’t help solve the housing crisis, or show you how to build affordable fireproof tornado-proof houses.

You don’t have to replant bamboo: the root mass sends up so many new shoots each spring that you can harvest some for food without reducing your timber crop. It yields 50 times as much fiber per acre as cotton, while its fallen leaves build a nice layer of humus to enrich the soil. Unlike chemical and water-thirsty cotton, bamboo needs no fertilizers, herbicides or pesticides. It is even easier to grow than hemp, and approximately as useful. And we need plantations of it all across the country, or I can’t help solve the housing crisis, or show you how to build affordable fireproof tornado-proof houses.

Tip Jar